TC Electric

Table of Contents

As a part of working at TCE, all employees are mandated to be track trained. This entails a MTA supervised trip into the tracks to learn how to act around moving equipment.

As a part of working at TCE, all employees are mandated to be track trained. This entails a MTA supervised trip into the tracks to learn how to act around moving equipment.

About

In the Summer of 2023, I interned for 11 weeks at TC Electric’s NY midtown field office. There, I worked on the Innovation Team with Jacob Shavel as my mentor. Together with Rachel, a fellow intern, we completed the Subcontractor Automation Project, a tool to guide Subcontractors through filling out required MTA forms.

Subcontractor Automation Project

The project was born out of necessity: the MTA requires subcontractor submittals to be completely correct, otherwise they would be rejected. This review process may take upwards of 1 month, meaning if TCE was gearing up for a contract and a form came back as rejected, all remaining work would have to be dropped. The subcontractor would need to fill out the form properly in order to resume work.

There are 10 MTA forms subcontractors are required to fill out. Each form contained multiple sections, and each section contained multiple parts and subparts. It was quite often subcontractos would fill out critical information incorrectly. In an effort to reduce the number errors, and thus the number of potential delays, we embarked on the journey to automate as much of the process as possible.

Rachel and I did SWOT (Strengths, Weaknesses, Opportunities and Threats) analysis on a set of ideas we came up with. We eventually settled on a Plumsail Forms as a flexible form builder. It supported programming using JavaScript, but integrated well with Microsoft SharePoint, TCE’s perferred internal network.

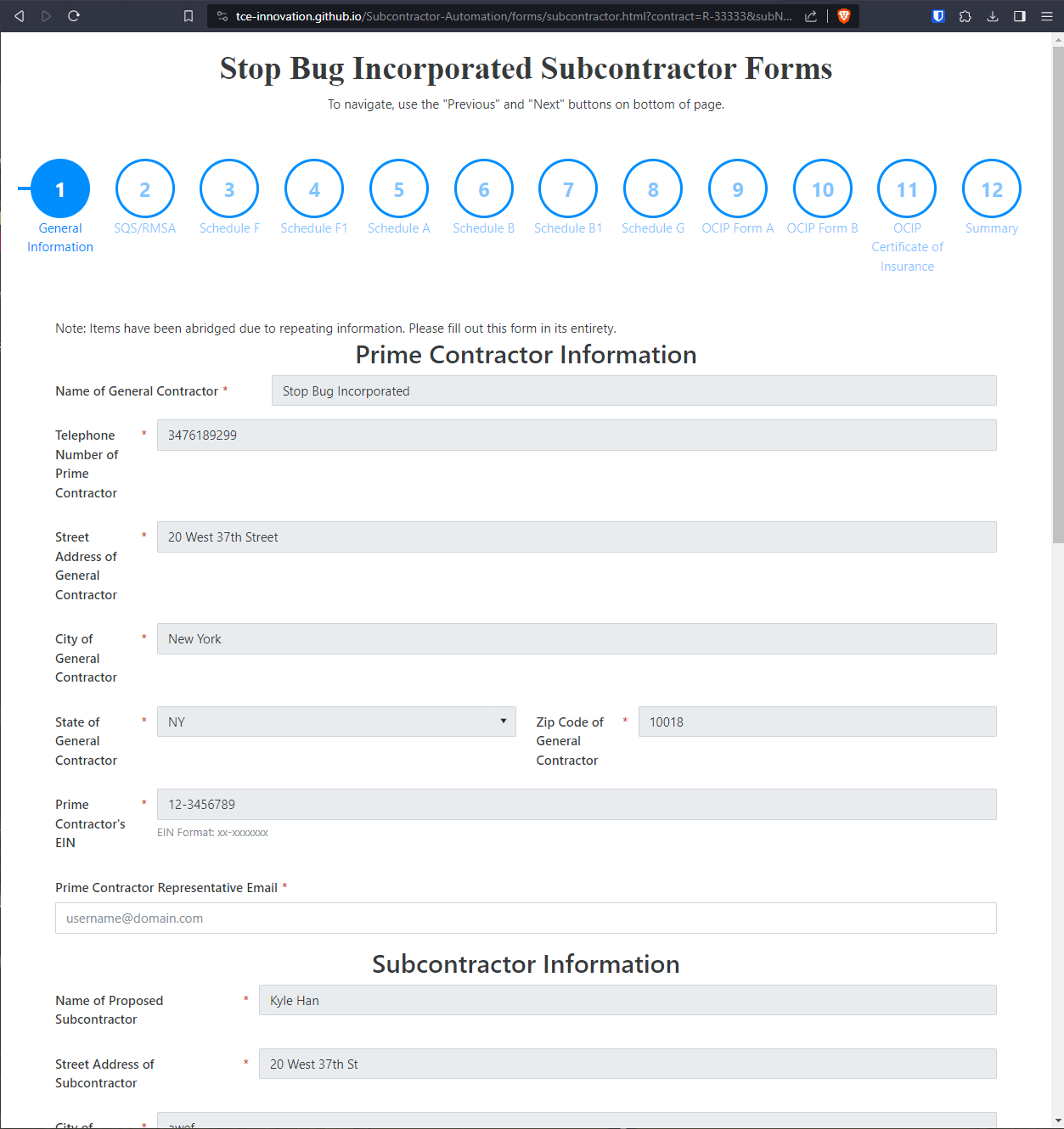

The end result is a wizard that guides subcontractors through filling out MTA forms, limiting the mistakes a subcontractor can make by error checking their inputs. Known good information was autofilled and disabled so that subcontracts can’t input wrong data.

A screenshot of the subcontractor wizard. Autofilled inforamtion is shown and grayed out.

A screenshot of the subcontractor wizard. Autofilled inforamtion is shown and grayed out.

Research Roundups

Over the course of 11 weeks, I produced 10 weekly reports about industry innovations. Every week, I would do a deep dive into a company, product, or idea that was developing in the construction world. The hope was to find future technologies that we could adopt to give TCE a competitive edge in the NYC construction market. Some of the exciting items I researched are as follows:

Field Images

The Abtus Routescan is an automation strategy the innovation team was testing to quickly take clearnace measurements when installing wayside equipment.

The Abtus Routescan is an automation strategy the innovation team was testing to quickly take clearnace measurements when installing wayside equipment.

After being set up, a train would bypass, completing the training on how to act while on the subway tracks.

After being set up, a train would bypass, completing the training on how to act while on the subway tracks.